Corrective Motion—Steps to generally be performed that happen to be in regular operating procedures and that happen to be activated when sure circumstances are exceeded.

Aseptic Processing—A method of processing pharmaceutical and health-related products that involves the different sterilization on the products and in the bundle (containers/closures or packaging materials for professional medical products) as well as the transfer from the solution into the container and its closure underneath microbiologic critically managed circumstances.

Exceeding the Notify level is just not essentially grounds for definitive corrective motion, but it really should a minimum of prompt a documented abide by-up investigation that may involve sampling approach modifications.

At last, the analytical electrical power might be drastically decreased by dilution on the contaminate. Due to such complications, rinse and/or swab samples need to be utilized together with the placebo strategy.

To stay away from airborn contamination we use ahu method.what is the course of ahu to keep up in n-1 area and ultimate processing area

Item Call Areas—Areas and surfaces in a very controlled setting which are in direct contact with possibly goods, containers, or closures plus the microbiological status of which may lead to potential microbial contamination of your item/container/closure process.

The next are definitions of some of the methods at this time set read more up to decrease the contamination rate in aseptic processing:

Ambiance that contains a flammable gas, a flammable liquid created vapor, or a combustible liquid produced vapor combined with air that may burn or explode, owning possibly a MESG (Greatest Experimental Harmless Gap)one) worth lower than or equal to 0.

Subsequent the investigation, actions taken might contain reinforcement of coaching of staff to emphasise the microbial Charge of the surroundings; additional sampling at enhanced frequency; additional sanitization; added product tests; identification of the microbial contaminant and its achievable supply; and an evaluation of the necessity to reassess the current normal working treatments and to revalidate them, if vital.

The surface area temperature from the enclosure shall not enhance beyond the required Temperature Course rating.

four.14 Throughout the execution of protocol, any discrepancy noticed shall be recorded and effects assessment performed as per the respective protocol. Once the execution and compilation of protocol, a qualification report is prepared.

Knowledge with isolators indicates that under usual functions pinhole leaks or tears in gloves signify the most important potential for microbiological contamination; as a result, Repeated screening of your gloves click here for integrity and area checking of the gloves is crucial. Floor checking inside the isolator may additionally be useful on an infrequent foundation.

The levels of cleanroom qualification are meticulously developed in order that cleanrooms meet the mandatory specifications for contamination Regulate and regulatory compliance. This method is comprehensive, involving a number of essential phases:

Frequent Assessment and Adjustment: Making use of present-day checking data to produce important changes to environmental checking regimes and risk mitigation techniques.

Ariana Richards Then & Now!

Ariana Richards Then & Now! Michael Bower Then & Now!

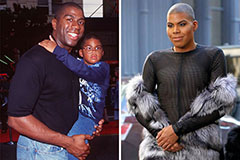

Michael Bower Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Lynda Carter Then & Now!

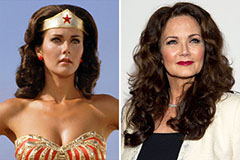

Lynda Carter Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!